After a day exploring the Blue Heron Mill site at Willamette Falls, my focus was on intervention and control. I saw a 6 ft concrete stem wall on the perimeter of the basalt bedrock falls, with an additional 3 ft wooden wall (seasonal) atop that. With a power plant on the opposite bank playing for maximum efficiency of flow, three large tubes inflate and deflate on command in the main spillway...The second largest waterfall in North America (by volume) had been transformed into a water fountain. So, as with much of industry, it seems that the natural wholeness and process is tethered to our need to achieve efficiency, comfort and control...

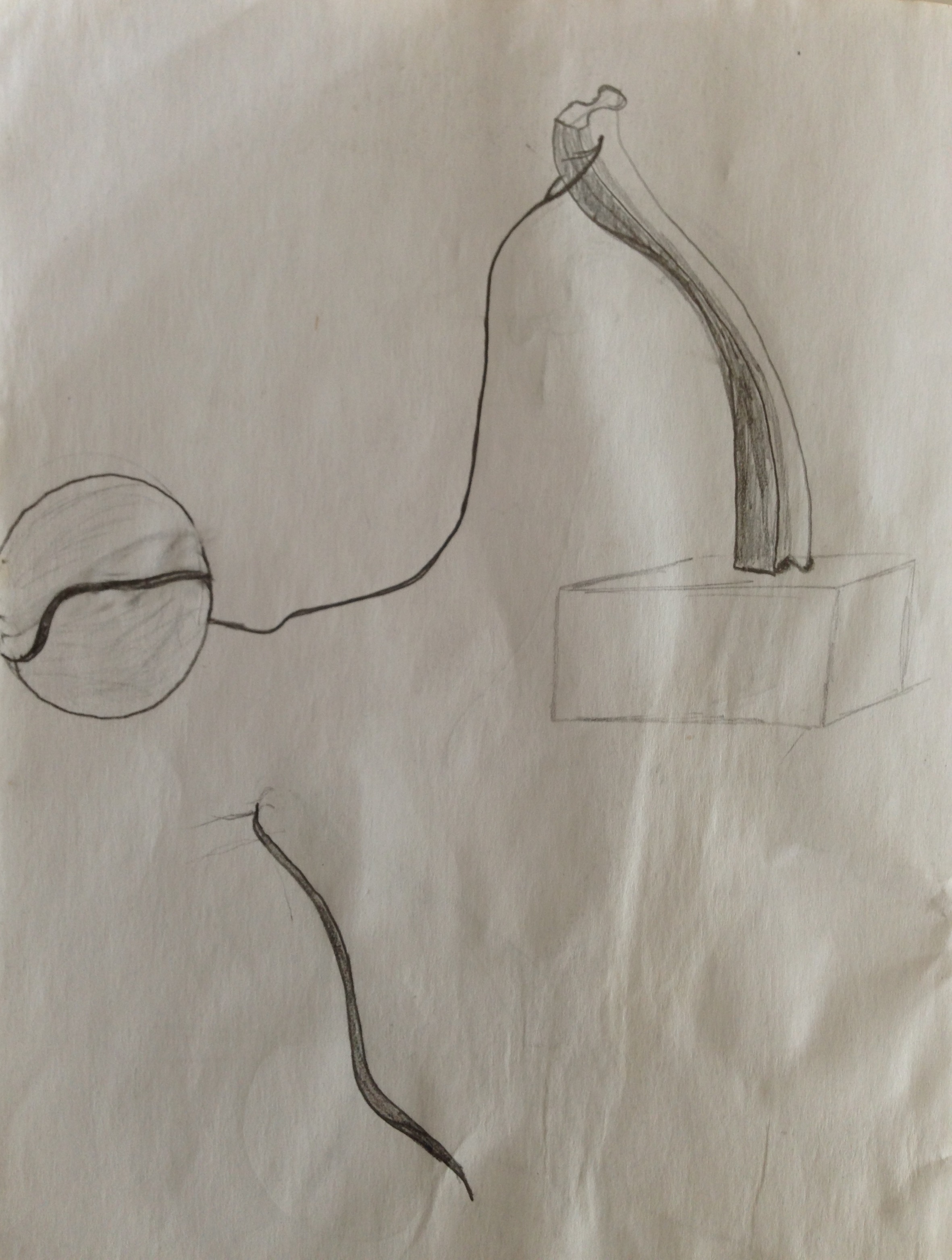

The rail and concrete represent industry, in use and strength. The rounded basalt, being the bedrock of the falls and the Blue Heron Mill site, speaks for natural wholeness. The cracks filled with concrete show the ways we've broken this wholeness and "fix" it to fit our needs. A process that seems continuous. The bent rail was found and packed out of a Nameless coastal river where high water inconceivably bent and broke the steel....representing nature's way of struggling to remain omnipresent but, with our ways, never able to be free.

Never carving stone before this was a huge learning curve in a short span of time. From start to finish i honed this block into a sphere and polished it in 10 days time. Learning tricks and short cuts on the way to make the process go faster, i did what i could to make this project come together on the due date. From hand chiseling to pneumatics to hot saw i quickly learned i was naive to think this process was done by hand.... and it may well be, but not in ten days, by me. It was a slow laborious process and most of the challenges came when i had to figure out how to rotate this behemoth stone. On my first attempt the rock blasted through one of my frame supports with out hesitation. I (we; help from friends at times) got smarter and better at controlling it as it rotated. It was a constant effort to work with the stone, not against it and all and all i am stoked at the outcome. For a project with zero budget i gave it my best and the response has been full of curiosity which i find encouraging.